The Role of Laminar Flow Hoods in Contamination Control

Particulate contamination is a constant and critical battle in sterile and aseptic techniques used in the pharmaceutical, technology, and healthcare industries. Laminar flow hoods are one of the most important pieces of equipment in these applications as they are designed to protect products on the work surface from particulate contamination. They are designed to help maintain the sterile workspace that is essential for a wide range of applications sensitive to particulates.

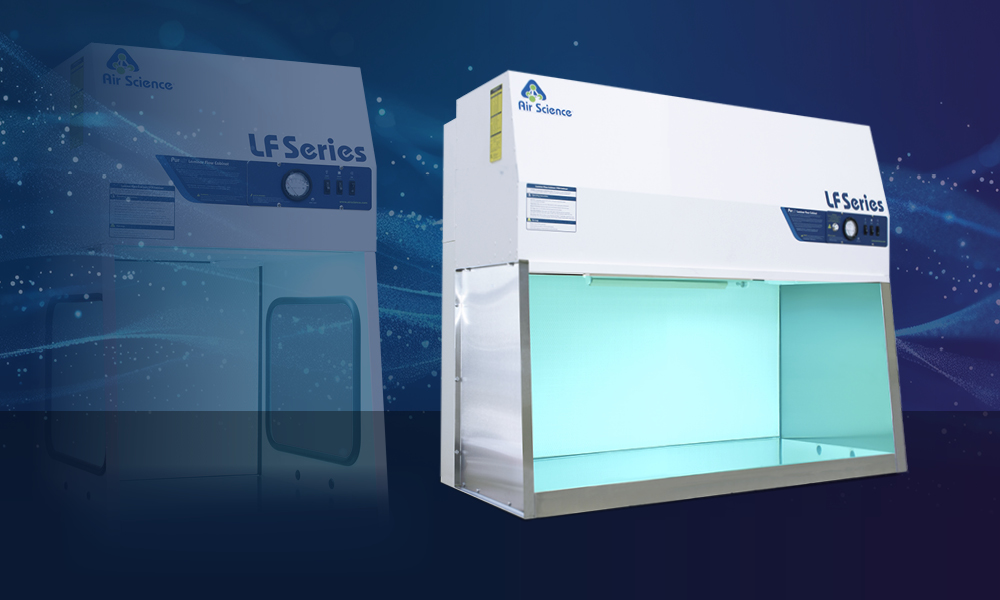

A laminar flow hood, also known as a clean bench, uses a HEPA (high-efficiency particulate air) filter or an ULPA (Ultra Low Particulate Air) filter to capture particles. Filtered air is then directed by a unidirectional, laminar flow that sweeps particulates away from items on the work surface. Unlike turbulent airflow, which can disperse contaminants, laminar flow ensures that the air moves in a unidirectional, steady manner. This effectively pushes away any contaminants and maintains a clean environment.

Unlike ducted or ductless fume hoods, clean benches only provide protection against particulate contaminants. Without an activated carbon filter, as with ductless fume hoods, or external venting, as with ducted fume hoods, laminar flow hoods are unable to capture fumes. They also do not provide protection for operators or the surrounding environment and should therefore never be used with harmful or potentially harmful substances. For applications that work with biological substances, microorganisms, or other substances that necessitate operator and environment protection, a biological safety cabinet (BSC) is more appropriate.

When should you use a laminar flow hood?

Laminar flow hoods are indispensable in a wide array of industries. Applications like pharmaceutical production and packaging, yeast propagation, electronic component assembly and repair, and other aseptic techniques greatly benefit from the particulate protection provided by laminar flow cabinets. They are commonly used in cleanrooms, laboratories, and hospitals.

Laboratory Laminar Flow Hood Uses

- Protect experiments and samples from external contaminants

- Help ensure the integrity of research results

Pharmaceutical Laminar Flow Hood Uses

- Maintain sterility throughout various stages of drug production, including formulation, compounding, weighing, packaging

- Ensure product integrity and safety

Food Industry Laminar Flow Hood Uses

- Yeast culture propagation

- Gourmet mushroom cultivation

- Food packaging

Technology & Electronics Laminar Flow Hood Uses

- Assembly and manufacturing of delicate electronic components, including medical devices, aerospace components

- Hard drive repair

- Cell phone screen repair

Healthcare Laminar Flow Hood Uses

- Maintaining sterile conditions during surgical procedures

- Medication preparation

Conclusion

Proper laminar flow hood cleaning is an essential component in maintaining the effectiveness of laminar flow hoods. Combining cleaning/sterilization of the work zone with good laboratory SOPs (standard operating procedures) helps create and maintain a sterile environment.

Routine maintenance, including filter replacement and calibration of airflow, is likewise crucial to ensure that the hoods continue to perform optimally.

By combining advanced technology with diligent maintenance, laminar flow hoods remain a cornerstone in contamination prevention and product integrity.

Learn more about Air Science laminar flow hoods, shop quality laminar flow cabinets online, or contact us with questions or unique needs.